OR why hydraulic fracturing of gas wells will lead to gas and other materials migrating to the surface via natural and induced faults and the well bore itself.

These videos are animations made by Marc Durand, Honorary Professor of Engineering Geology, Earth Sc Dept. Univ. of Quebec. They are about the Utica shale, a layer generally much deeper than the Marcellus, but the discussion is equally applicable to drilling into the Marcellus layer. To see more about the the underground salts corroding the cement casing as well as the metal piping SEE Prof. Durand’s paper, “SHALE GAS – A BUSINESS PLAN VERY MUCH IN THE RED”

QUOTE FROM Marc Durand: [The conclusions in my paper on the Utica are] relevant to other shales, including the Marcellus. Especially the main point in my paper (CONVENTIONAL GAS vs HYDROFRACTURING GAS SHALE) related to the long term geological process — the exponential decrease curve of gas migration toward the new fractures – is the same in all shale fracturing exploitation. The commercial extraction leaves 75-80% of the methane in all shales, for this long term life of the future abandoned and aging wells. A serious threat for the future generations and a cost much greater than the short term $ benefits.

Shale Gas 101: Case of the Utica in Québec

From: gasdeschiste, May 7, 2011Original documents at: www.facebook.com/shalegas

This video explains the geological and technical aspects of the proposed exploitation of the Utica shale gas in the densely populated area between Montreal and Quebec. The technical documents discusses the very serious technical limitations and flaws of the fracking method. It shows why only a mere 20% of the gas can be extracted by this technique, and the serious consequences that this will imply, with the remaining 80% of methane that will slowly but continuously for years and centuries, flow from the fractured shale.

My 2nd video “Shale Gas 102 – The Experiment” is available now.

by Marc Durand, honorary professor of engineering geology, Earth Sc Dept. Univ. of Quebec, –English narration: Ingrid Style/ G. Beaulieu

Shale Gas 102: The Experiment

From: gasdeschiste, June 30, 2011This video summarize the geotechnical analysis in my documents posted on this site: www.facebook.com/shalegas. The shale gas industry was started without any consideration for the medium and long term consequences that will be far more costlier than the short term benefits. In 3D modeling, the oval reservoirs are 2000 m below the surface, the green reservoirs are each 1000 m long x 200m high; you can fit a 60 stories skyscrapers vertically in it.

by Marc Durand, honorary professor of engineering geology, Earth Sc Dept. Univ. of Quebec,

–English narration: Ingrid Style/ G. Beaulieu

More from Professor Durand:

http://www.facebook.com/notes/shale-gas-info/conventional-gas-vs-hydrofracturing-gas-shale

CONVENTIONAL GAS vs HYDROFRACTURING GAS SHALE

by Shale Gas Info on Saturday, March 12, 2011 at 5:03pmThe Exploitation of Conventional Gas Wells vs Exploitation by Extended Horizontal Drilling and Hydraulic Fracturing.

(Translated by Ingrid Style)

Why isn’t it possible to extract more than 20% of the gas in a shale gas deposit and what are the consequences of that fact? Notwithstanding the still limited knowledge we have of the long term impacts of the technique of hydraulic fracturing in extended horizontal bores, we shall analyze the more obvious differences between this new technique and classical gas exploitation.

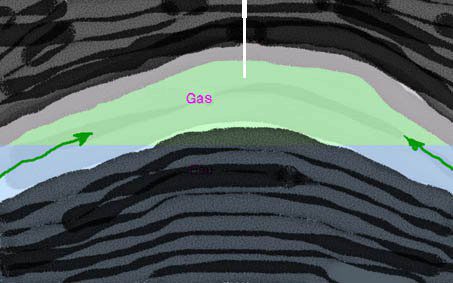

In conventional exploitation, the gas deposits are found in specific geologic structures: a formation or geologic structure of great porosity resulting from inter-granular spaces and/or natural inter-connecting fractures, the whole capped by a watertight formation which seals the top of the reservoir, as in the schema below.

Figure 1. Conventional natural gas reservoir, in which the gas migrated over geologic period of time to reach a porous and/or natural fracture zone.

Once the gas vein is found, following a real geologic exploration, the extraction well drilled into the reservoir is able to extract almost all (>95%) of the gas in the deposit. The gas is propelled to the surface by the water. (there is a possibility of liquid hydrocarbons between the water and the gas). It is important to note that this gas has VERY slowly migrated from a matrix (a sedimentary rock which may be shale for example) and has accumulated in this natural reservoir in a process which has taken hundreds of thousands of years, and more probably millions of years. Why? Because the shale matrix has a very low permeability coefficient (10exp-6m/s). In exploiting a natural deposit then, the gas migrates easily towards the extraction well. Thus eventually the production of the well falls to zero. The reservoir is not 100% empty, but almost.

It is extremely dangerous to extrapolate from the above scenario to that of shale gas: in the case of shale gas the fracturing is immediate and we do not reach equilibrium at the end of the exploitation. Moreover, the effects are not limited to a local deposit but extend to radically transform an entire layer.

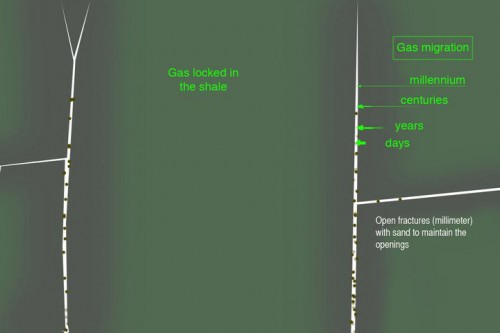

In the case of artificially fracturing the shale gas deposit itself, the gas migrates over a shorter distance than the long migration of the classical natural gas, but it is not an instantaneous process. Within a few mm of the edge of a fracture, the gas escapes fairly quickly (see below), but the greater the distance, the more one must count on geologic time for the process of migration to happen in the new shale as it once occurred with the natural reservoir. With a permeability of 10-12 cm/s, for example, even under a gradient (i) elevated by 100, the time required to traverse only a few centimetres is on the order of centuries or even millennia (v = Kxi). That is how things work in the parts of the shale which remain intact between the fractures . But because of the steep gradient, migration will occur.

Figure 2. Gas migration in the shale in proximity to the new fractures; metric view of shale at the end of exploitation (5 to 8 years?).

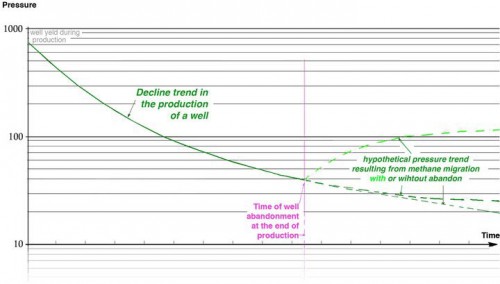

The exploitation by hydraulic fracturing produces elsewhere descending logarithms, or exponentials as in the figure below for the Marcellus.

Figure 3. Theoretical production rate decline for the Utica shale, based on what is observed in the Marcellus.

The output is only commercially viable for a few years; it is absolutely absurd to say (as did the Talisman geologist * ) that afterwards there is no more gas and one seals the wells. There is no zero output until time reaches infinity, in this type of curve.

On top of this, the National Energy Board estimates that the extraction leaves 80% of the gas in the shale. Nothing will stop the process once begun. It will continue for centuries and millennia. The well caps do not have a comparable lifespan. It would be truly astonishing if the the gas industry has in the last eight years invented structures capable of lasting for millennia. The ongoing gas migration will slowly restore pressure in the wells. After a geological time span, this new level of fractures may become a comparable deposit to the conventional gas deposit.

Civil engineers always would have loved to have techniques to make viaducts and bridges last more than fifty years. Here, the gas industry, with the same materials, steel and concrete**, is asking us to believe that they have the recipe for thousands of capped wells to eternally resist the growing pressure in a great fractured Utica reservoir, under our feet in the St Lawrence Valley.

The case of the 31 wells already drilled

I suggest that we quickly find a method of managing the wells already in place; about half have reached the hydraulic fracturing stage, which reduces the number requiring treatment to less than twenty. But this nevertheless means a several sites to manage. The public absolutely must not, one day, inherit this task.

The gas industry which effected the drilling must insure its future management in the very long period following its exploitation. Legislation must be reviewed to insure that the responsibility for the wells remains with those who dug them.

The present government has a penchant for projects in which the the private sector constructs, exploits, maintains, etc . This style of management should be the one applied to the 31 wells . By means of a 99 year lease with compulsory renewal at the end of this time, each of the well owners would have complete responsibility and should hold insurance and a guaranty of solvency. Being responsible for any problem that may manifest will change the game. The industry should not balk at this obligation, because according to what it asserts (and contrary to what I believe), there will be no problems. Personally, I am convinced that rigorously imposing this sole requirement, will be sufficient to completely halt further activity here in the Utica.

The idea of obligating the constructors of the wells for 9 times 99 may appear preposterous on first blush, but I cite a source that the industry should not contest : Halliburton. On the pages that deal with gas shales, there is not one line on the long-term risks. But on other pages dealing with CCS (Carbon Capture & Storage) the Halliburton techniques of sounding and repairing the ageing wells are lauded: in cycles of soundings- repairing- returning to a phase of soundings, all this over centuries, even millennia . > http://www.halliburton.com.

These wells that Halliburton indicates should be followed for millennia are à priori less risky than the wells with horizontal extension and hydraulic fracturing: these are vertical wells connecting on the surface with CO2 storage tanks, less problematic than methane. The gas industries are not ignorant of the long term risks; they are only pretending that these don’t exist and that the wells can innocuously revert to the public domain. There is no regulation anywhere which obliges them to include these long term risks in their business plans. On the other hand, they know they must act quickly because the situation can change.

In conclusion

There are two important differences between shale gas and conventional gas deposits andthese two differences provide in themselves the fundamental reasons for rejecting totally the ill-considered idea of shale gas exploitation by means of the currently proposed technique:

1) Hydraulic fracturing artificially creates a network of interconnected fractures towards which the gas begins to migrate. The technique initiates the flow of gas in the deposit as happened in the classic natural gas deposits over hundreds of thousands of years, but the technique can not speed up the geologic process. The construction of a well and its fracturing are completed in a few week; the flow begins and continues on a geologic time scale (greater than 100,000 years). The amount of time before the well is closed (once the rate of flow is no longer commercially viable) represents no more than an infinitesimal portion of the geologic time.

2) The drilling of wells and the fracturing of the homogeneous rock is a totally irreversible operation with no technical solution to restore the the shale to its original impermeable state. These gas wells closed off at the end of commercial exploitation become potential conduits for the gas leaks. For these structures, as all structures made of steel and concrete, there is the fundamental question of their life span – from which follows the question of what will happen when their state of degradation can no longer withstand the pressure of the gas. This pressure in the reservoir will grow slowly but continually while the well structures will continue to degrade. These two phenomenon will in time become manifest on the surface in the growing number and increasing flow of methane leaks. The management of these buried works will cost colossal sums.

Marc Durand, doct-ing en géologie appliquée Professeur retraité, dépt. Sciences de la terre, UQAM

*https://rochemere.blogspot.com/

**more precisely cement grout in the case of the wells and not real concrete; the grout is a great deal less resistant and durable than real concrete.